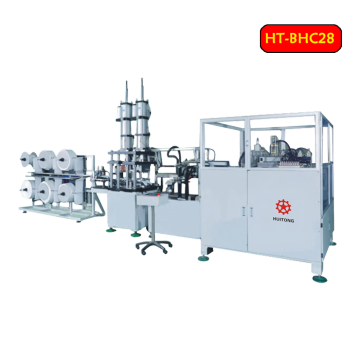

Click on the follow link to find out more information: http://www.medicalmaskmachines.com/medical-mask-machine/

Company Info

- Company Name: Dongguan Huitong Automatic Machinery Technology Co., Ltd

- Representative: Weibin Chen

- Product/Service: Mask Machine , N95 Cup Mask Machine , Medical Face Mask Making Machine , Shoe Cover Machine , Ultrasonic Quilting Machine , Non-woven Machine

- Capital (Million US $): US$1 Million - US$2.5 Million

- Year Established: 2012

- Total Annual Sales Volume (Million US $): US$1 Million - US$2.5 Million

- Export Percentage: 1% - 10%

- Total Annual Purchase Volume (Million US $): US$1 Million - US$2.5 Million

- No. of Production Lines: 10

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 61 -70 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 1,000-3,000 square meters

- Factory Location: 37th Alley Num 2,Xincun Yangjiang Rd.(E),Wangjiang District,Dongguan city

- Contact Person: Ms. Shellian Tang

- Tel: 86-15814156165

Email to this supplier

Premium Related Products

Other Products

Hot Products

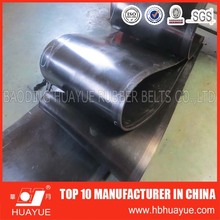

PVC/Pvg Whole Core Fire Retardant Conveyor Belt 680s-2500sPVC/Pvg Whole Core Fire Retardant Conveyor BeltCold Resistant Rubber Conveyor Belt (-65c ~ 70c)Belt Idler Conveyor PulleyOil Resistant Conveyor BeltConveyor Roller Idler Brackets (D75, TDII, TDIIA)Cotton/Cc Conveyor Belting for Heavy Duty (CC56)Chevron Pattern Conveyor Belts (B400-2200)Endless Flat Nylon Rubber Sidewall Conveyor Belt Width 300-2200mmUnderground Coal Mine PVC/Pvg Fire Retardant Conveyor Belt (680S-2500S)Dia 102mm High Quality Rollers Heavy Laoding Impact Idler RollerHigh Quality Steel Cord Conveyor Belt ManufacturerNylon Fabric Rubber Conveyor Belt Nn100-Nn600High Quality Nylon Core Conveyor Belt with International StandardEp Polyester Multi-Ply Rubber Conveyor BeltHeat Resistant Ep Fabric Rubber Conveyor Belt