The maintenance of SMT machines

Basic Info

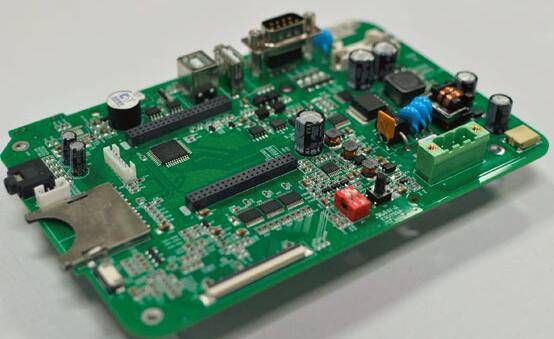

Model No.: assembly 03

Product Description

How to maintain of SMT machines?

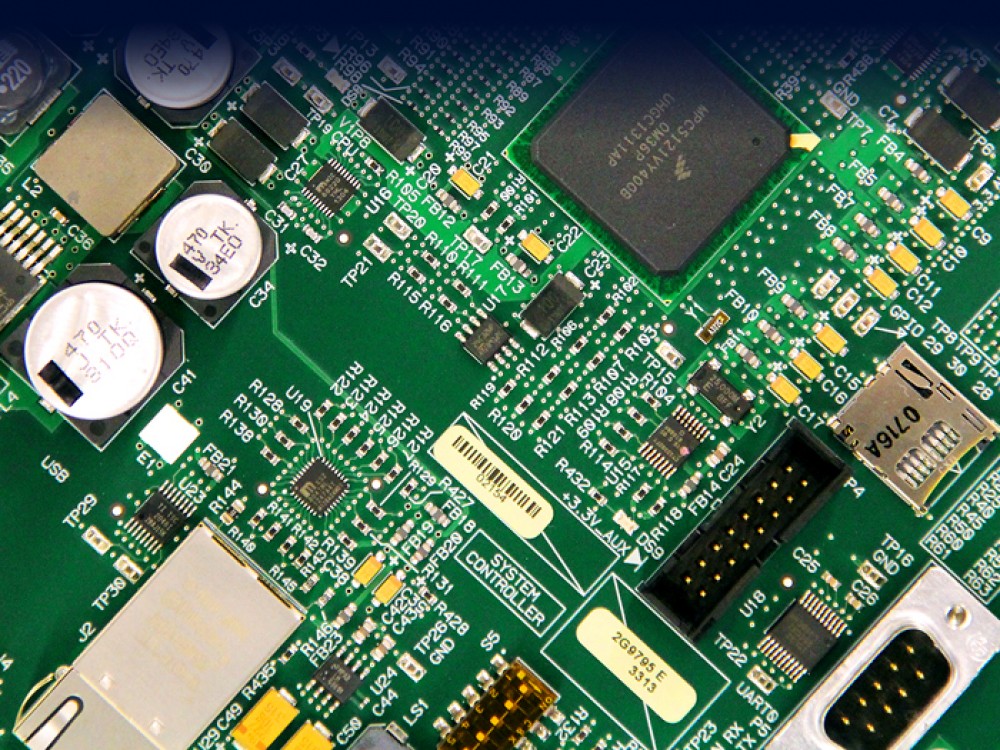

Mounting machine: also known as "mounting machine", "Surface Mount System" (Surface Mount System), in the production line, it is configured after the dispenser or screen printing machine, by moving the placement head to mount the surface A device where components are accurately placed on the PCB pad

The SMT placement machine is the most core automation equipment in the SMT process. It is a highly automated production equipment, which is equivalent to a placement robot. For this kind of high-precision production equipment, it must be properly maintained on a regular basis. For smt chip processing manufacturers, the placement machine is the rice bowl for eating, so how to maintain the SMT placement machine is a problem that must be considered.

How to maintain the placement machine?

1. Pay attention to the nozzle clamp to check the buffering action. If the action is not smooth, apply a thin layer of lubricant, if the clamp is loose, tighten it.

2. Move the lens to clean the dust and residue on the lens. Check the Y-axis and X-axis screw. Check that the screw has debris or residue, and clean it if necessary. W-axis screw check that the screw has debris or residue, clean the air interface if necessary, check the Y-shaped sealing ring and O-ring are aging, and replace if necessary.

3. The monthly inspection of this part should be carried out according to the nozzle type and nozzle changing station.

4. Check the O-ring used for each nozzle shaft. If it is aging, replace it in time.

5. Wipe off the dust and residue on the X-axis screw, and apply a thin layer of grease by hand.

6. Wipe away the dust and residue on the Y-axis guide rail, and apply a thin layer of grease by hand.

7. Check the movement of the Z-axis rack and pinion, and if necessary, apply a thin layer of lubricant on the rack transmission parts by hand.

8. Check the wear and tightness of the R-axis transmission belt, and replace the belt or adjust its tightness if necessary.

9. Wipe away the dust and residue on the W-axis screw, and apply a thin layer of grease to the feed valve by hand to check whether the solenoid valve can work normally. Check the wear and tightness of the Conveyor Belt, if necessary, replace the belt or high-speed its tightness.

10. The maintenance of the placement machine should clean, dismantle and wash the dust and scale on the surface of the machine and the circuit board, so as to avoid poor heat dissipation inside the machine due to the dust and scale, causing the electrical parts to overheat and burn out.

11. Disassemble and clean the internal air circuit, solenoid valve, vacuum generator, cylinder, etc. of the placement machine. If the grease in the gas path cannot be cleaned in time, it will block the gas path, which will also cause the gas path to be unsmooth and cause high dumping; and even the oil stains accumulated in the gas path will also corrode. Loss of various internal sealing rings and components such as solenoid valves, vacuum generators, cylinders, etc. will cause damage to the components.

Product Categories : PCB Assembly Products > Turkey PCB Assembly